Assembly machines

Automated or semi-automated, Cermac assembly machines are all custom designed in full respect of our customers’ specs. We aim to increase not only precision and output but also safety and wellbeing on the job by avoiding complex and dangerous movements, in particular.

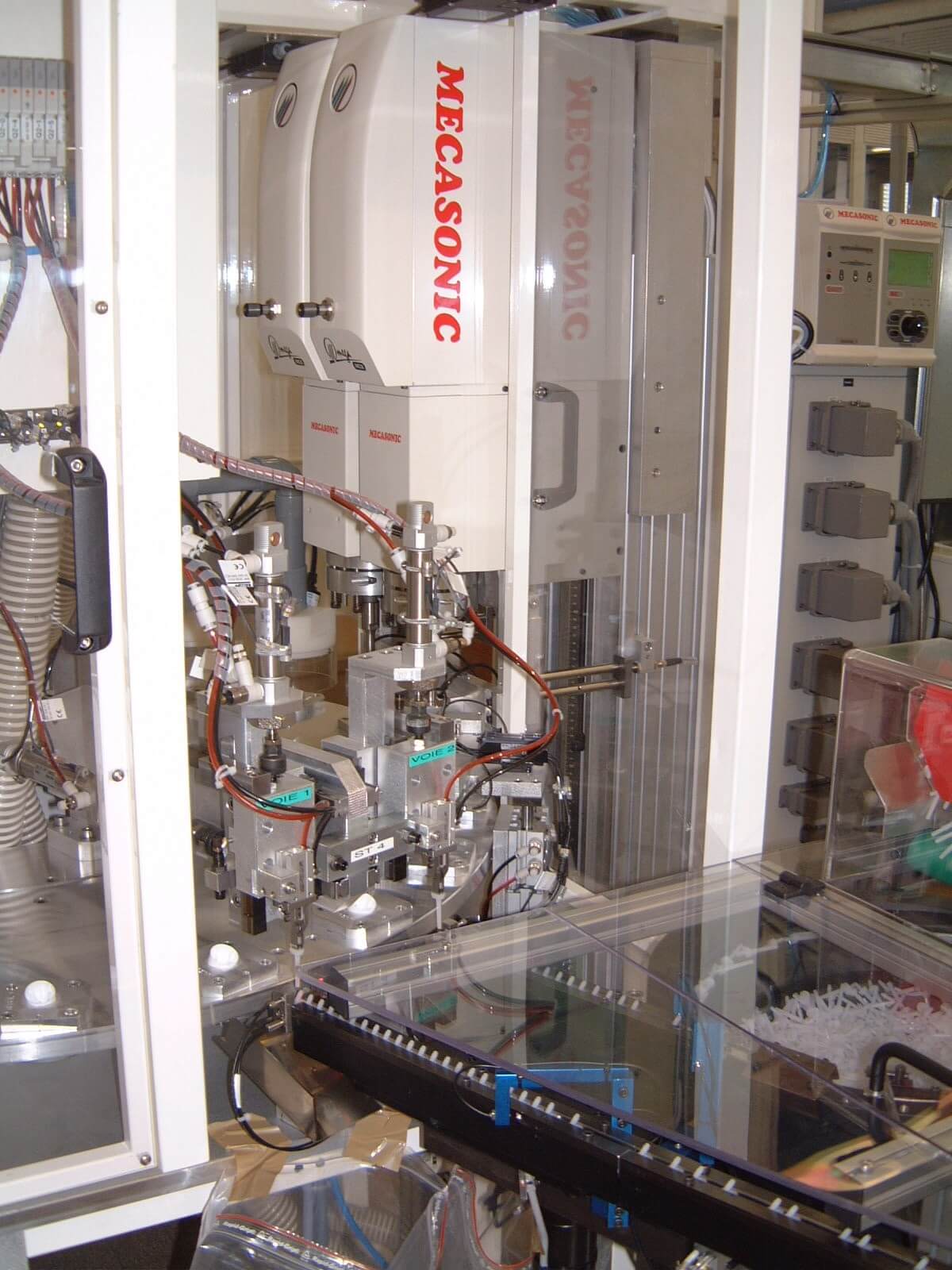

1- Automated assembly machines

The most important quality in an automated assembly machine is its ability to withstand elevated output rates. It will be specially designed by our Engineering Department as the optimal solution for your meticulousness, performance, and productivity. The principle of assembly is based on indexed movements (rotating table or linear indexing). Depending on the output rate and the complexity of the parts, we will propose pneumatic, cam, or electrical assembly solutions. We can integrate various functions into our assembly machines:

ultrasonic welding

size check (visual, laser, tracer, etc.)

flow/watertightness test

label placement

tightening torque check

machining, drilling, internal threading, and milling units

2- Semi-automated assembly machines

The semi-automated assembly machine is the perfect partner for operators when the product characteristics are not suited for a fully automated system: special forms, non-standard sizes, unadapted weights, etc. Once placed on the mount by the operator, the product can then be assembled automatically. This semi-automated assembly machine is manufactured taking into consideration the ergonomics required in a workstation.

Examples:

crimping machine

semi-automated cutting machine

semi-automated assembly machine

insertion machine